------Houston------

24/7/365

(713) 453-6677

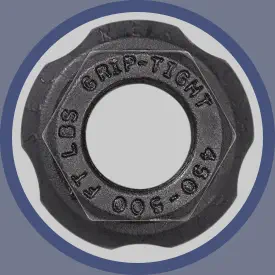

GRIP-TIGHT Nut

The HYTORC GRIP-TIGHT Nut is the new Wheel nut for your commercial fleet. The patent design eliminates the influence of side

load and provides a pinch point free reaction component for applied torque. Proudly manufactured in USA.

Protect your commercial fleet from wheel installation related incidents with the new HYTORC GRIP-

TIGHT™ Nut. The GRIP-TIGHT™ Nut is an instant upgrade for all heavy-duty truck and trailer hub piloted

wheel. The patent pending GRIP-TIGHT™ Nut eliminates the influence of side loads and provides a pinch

point free reaction component for applied torque. The GRIP-TIGHT™ Nut allows for controlled and safe

torqueing with convenient cordless tooling systems. Call to request a demonstration of HYTORC

cordless tooling system in conjunction with the GRIP-TIGHT™ Nut.

GRIP-TIGHT™ Nuts can be torqued and

loosened with common impact guns and

wrenches. The patent pending washer profile

includes a special geometry for rotationally

coupling to the HYTORC reaction socket. This

washer acts as a coaxial reaction point, thereby

eliminating pinch points and removing undesirable

side loads. These benefits make it feasible to

upgrade to cordless digital tooling systems while

increasing the efficiency, quality and safety of

wheel nut installations.

Loading Surface

GRIP-TIGHT™ Nuts have M22X1.5

threads, 33mm hex, 27mm height and a

46mm washer diameter. The two-piece

GRIP-TIGHT™ Nuts comply with technical

requirements of SAE J1965. Cross

Reference PN’s: 39773, 39874, 39702,

M3979, 39691, 39949, 201.3013, 13-3057,

E-9020, W-525, R009020, 511034,

KB9020,WA075037, 20857204,

1649492C1, E6HZ-1120-A, MF110343, and

MF111026

Material and Design

The made-in-the-USA GRIP-

TIGHT™ Nut is produced from

through-hardened carbon steel and

each free spinning washer is made

from through-hardened and

tempered chrome-moly steel. The

GRIP-TIGHT™ Nut geometry and

coatings combine to create a

consistent and efficient translation

from torque to clamping force

Materials